SOFTWARE

SOFTWARE SOLUTIONS

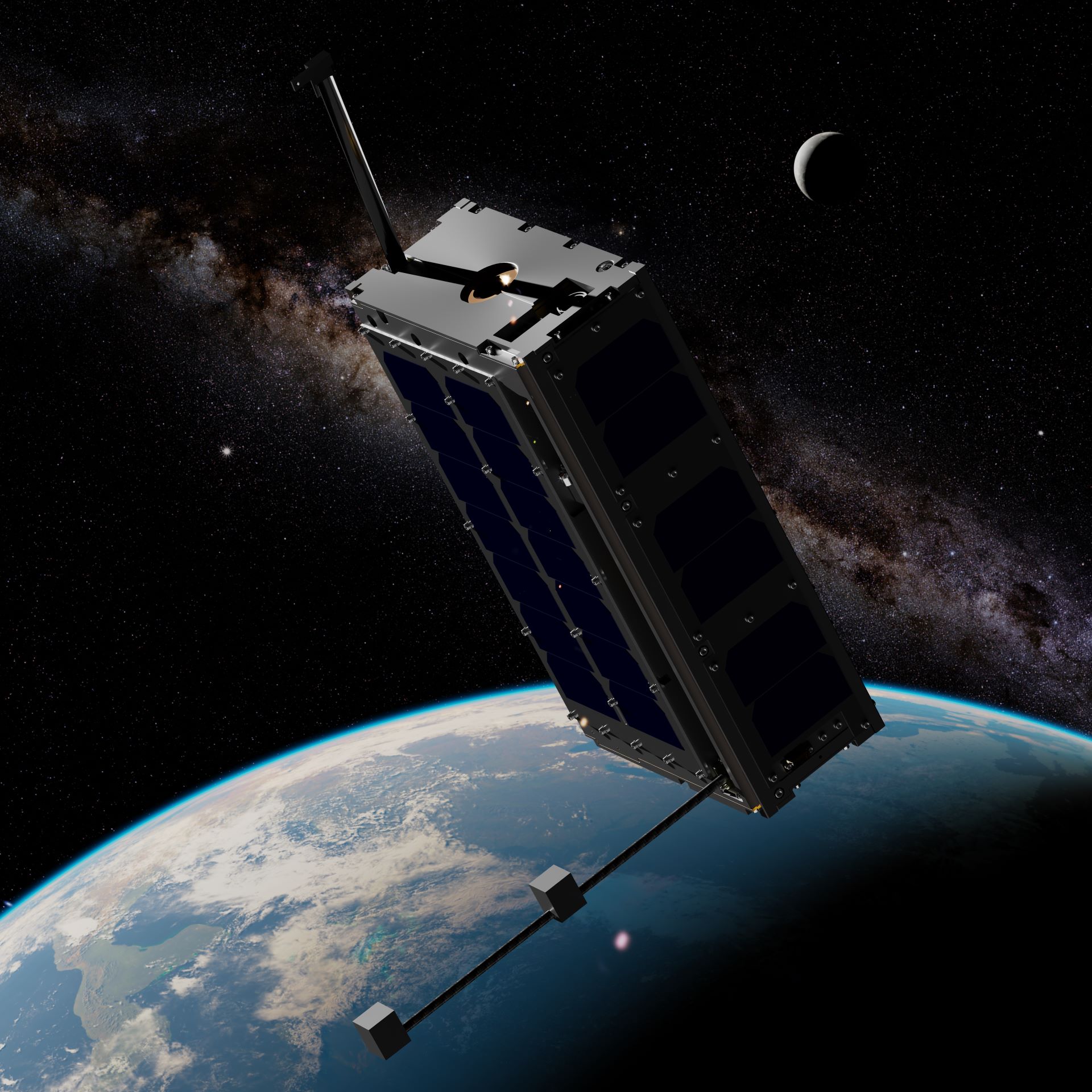

Our team builds custom flight software and firmware with high reliability and efficient hardware integration. We handle everything from communication protocols and control algorithms to diagnostics and telemetry. We are ready to tackle whatever challenges your project offers.

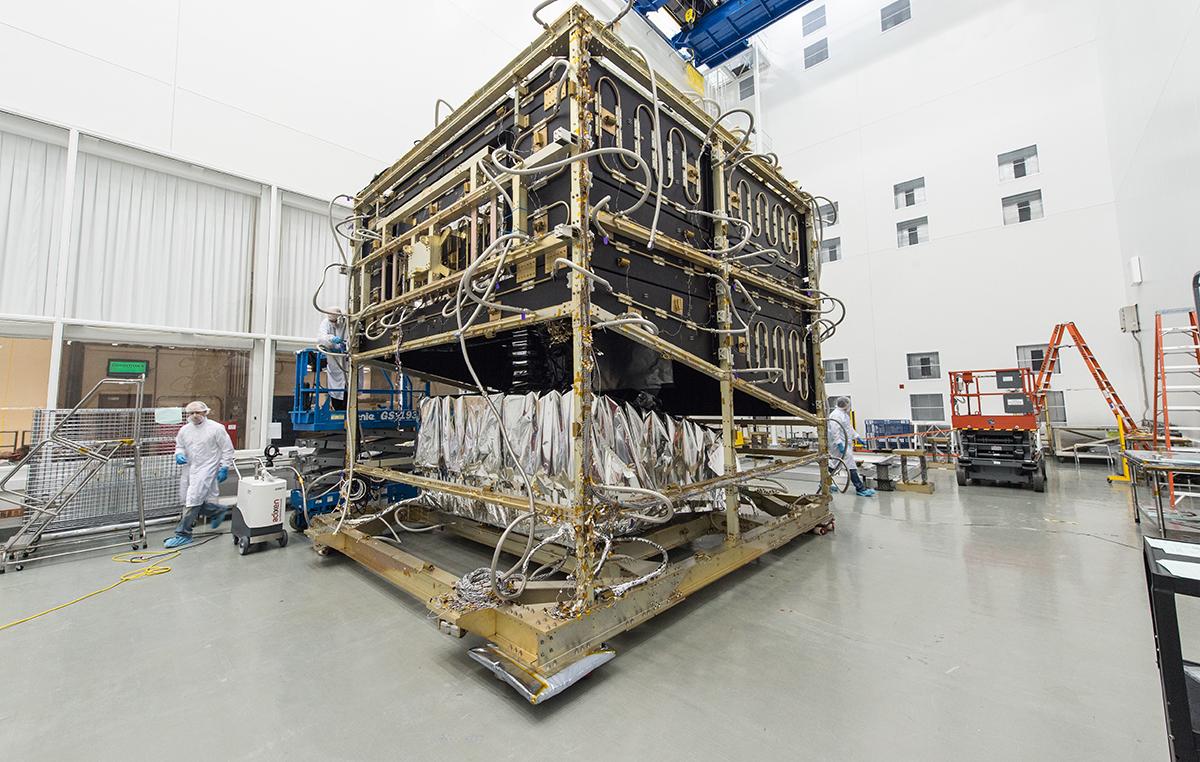

SYSTEM INTEGRATION

From bare metal applications to user interfaces, our versatile software team has your needs covered. Our capabilities include:

- Custom flight software & firmware

- Bare metal applications for hardware-software interaction

- Resource usage optimization for constrained environments such as embedded systems

- Data storage design & implementation

- Design & test communication protocols such as UART, SPI, I2C, and Ethernet

- Program & tune control loops such as PID controllers

- Automate workflows

- Data analysis

- Version control & collaborative development workflows

- System level functions such as diagnostics, fault detection, and recovery

- UI for telemetry and command

- Software Defined Radios (SDRs)

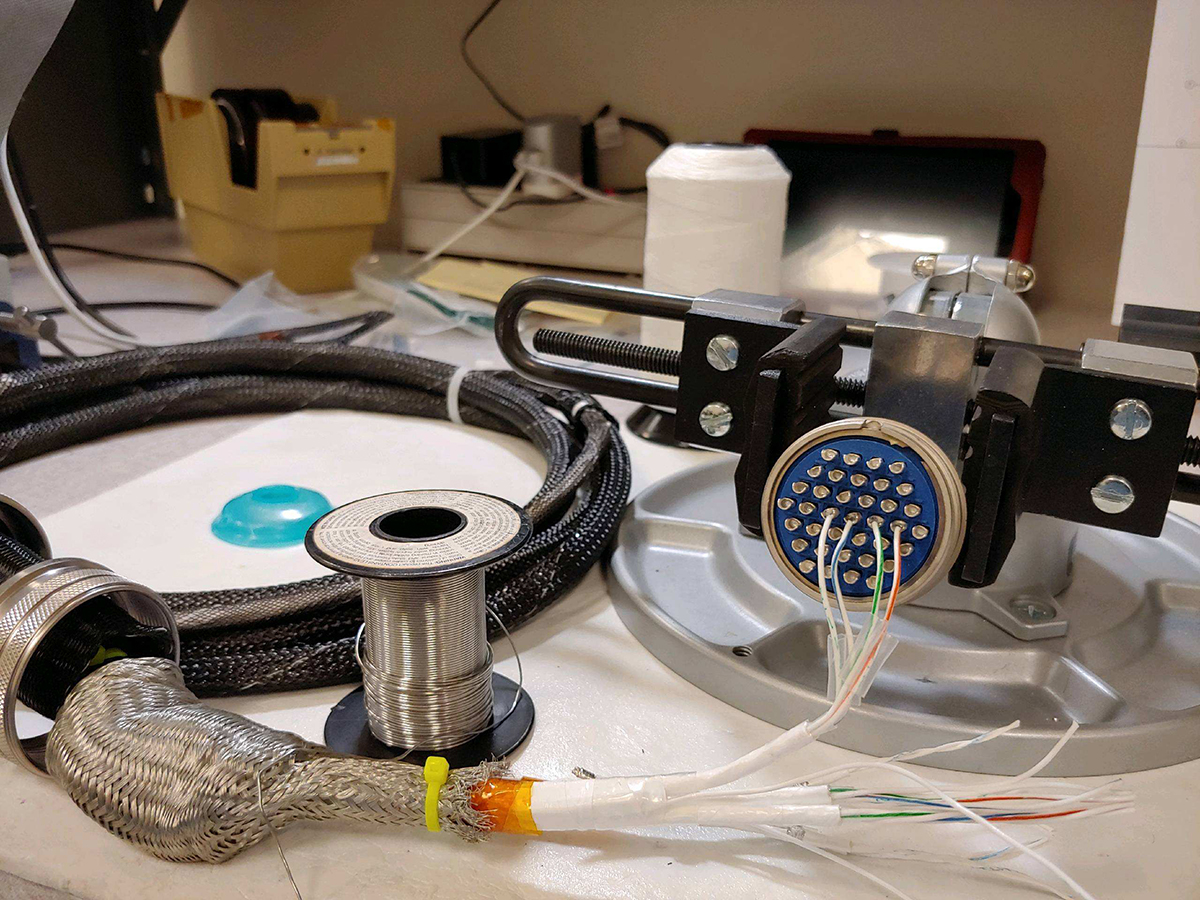

DETAILED SOFTWARE DESIGN

Our software team has experience with a wide range of software to create the best solutions for your specific needs:

- COSMOS

- Git

- Vivado Design Suite

- PetaLinux

- cFS

- HyperLynx

- SolidWorks

- AutoCAD

- Altium

- OrCAD

- PADS

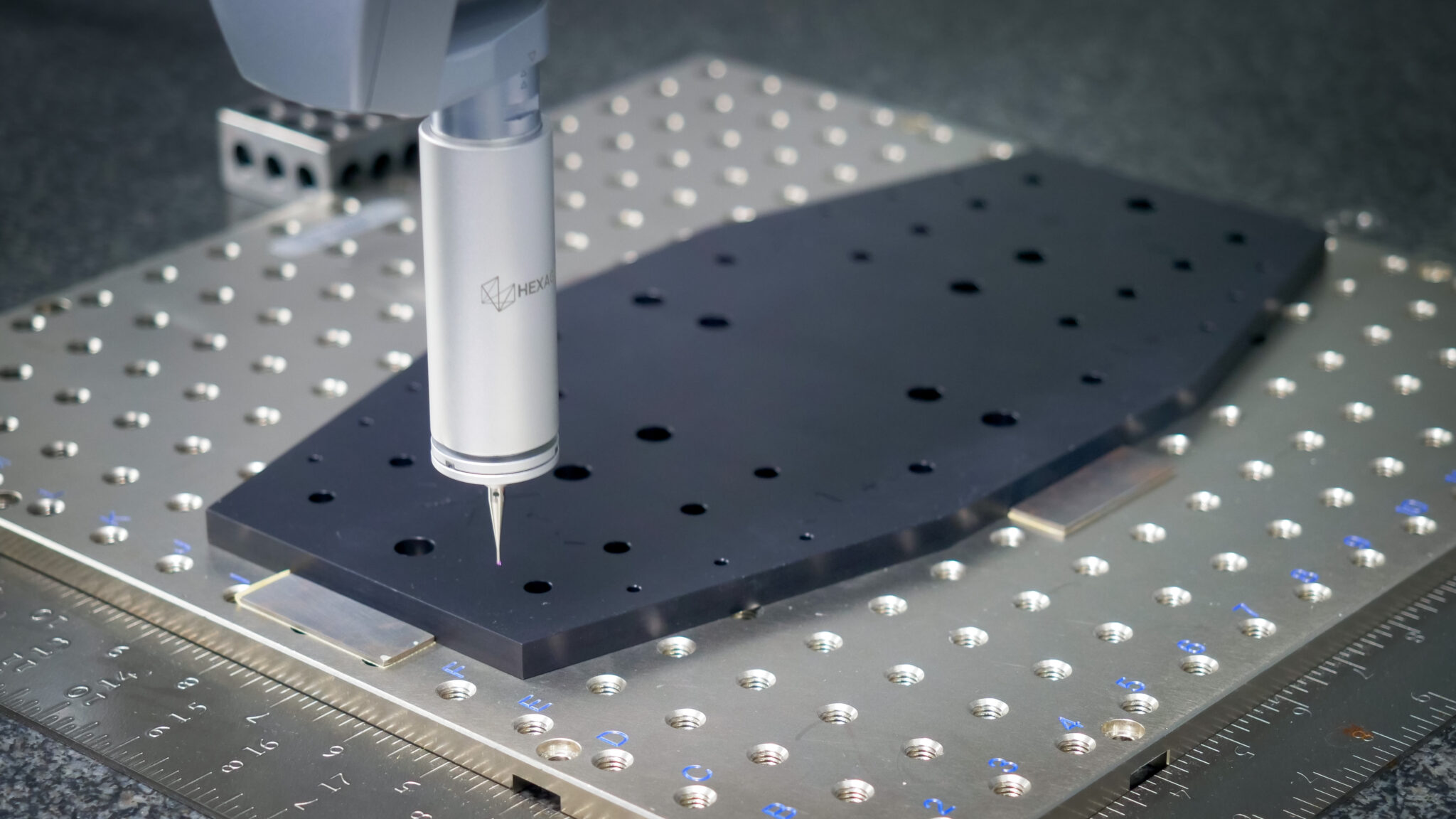

Need hardware in addition to software? Check out our flight avionics capabilities:

LANGUAGES & OPERATING SYSTEMS

Languages:

- C

- C++

- Python

- Ruby

- Verilog

- VHDL

- MATLAB

- HTML

Operating systems:

- Linux

- RTEMS

- Windows