Hubble Servicing Missions

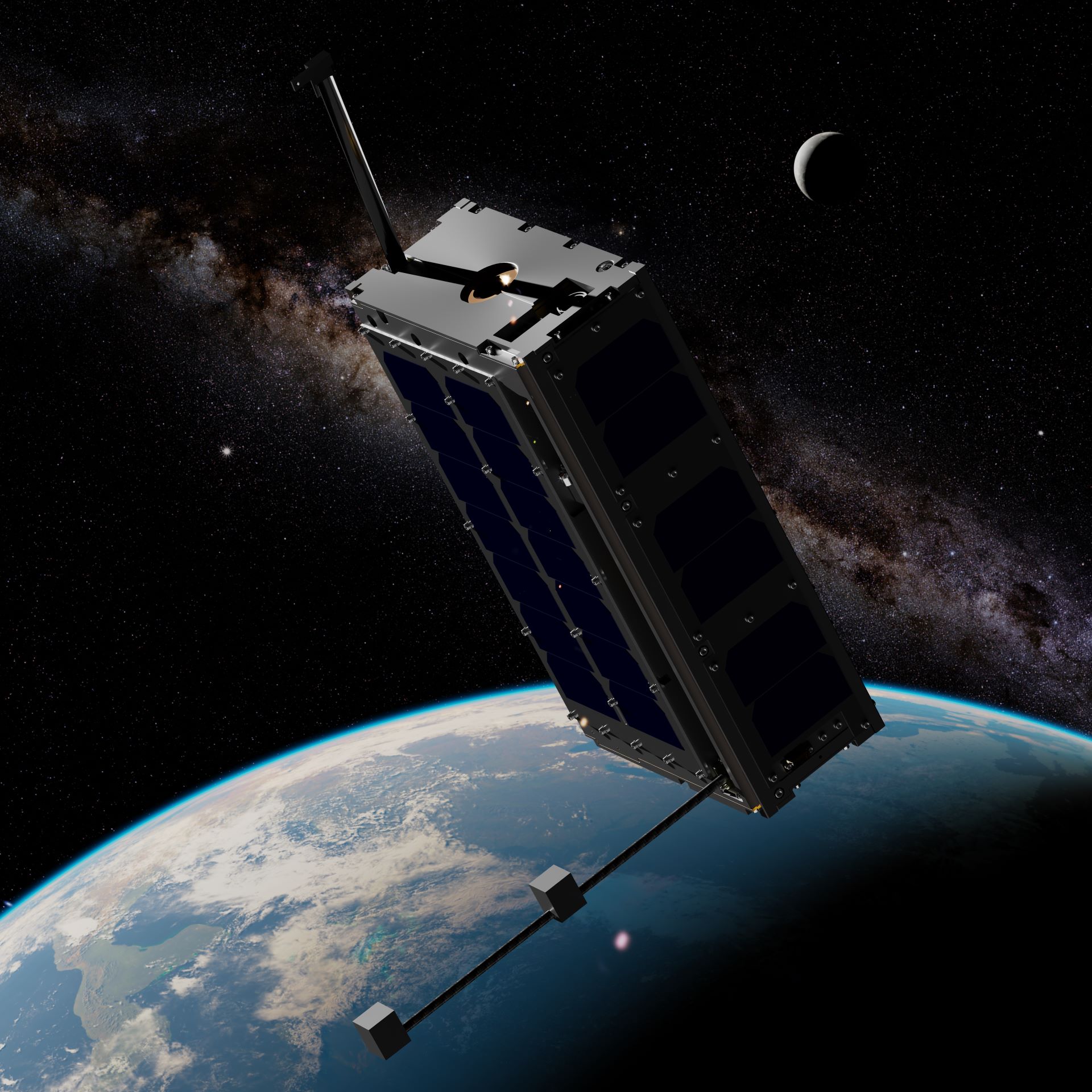

Overview

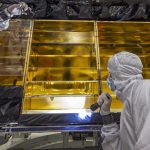

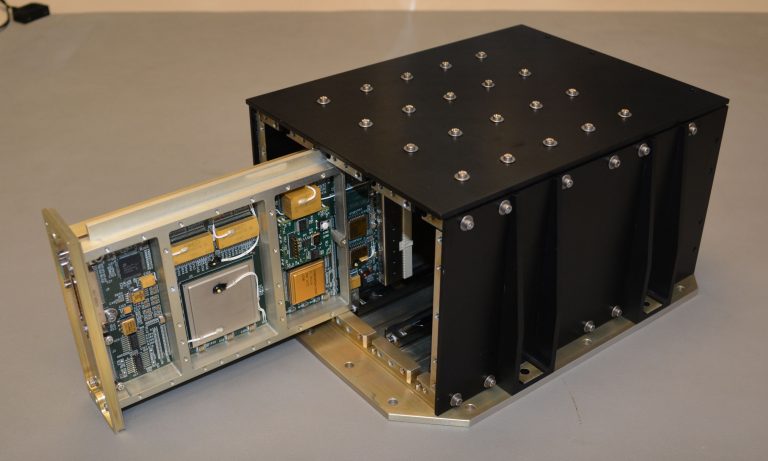

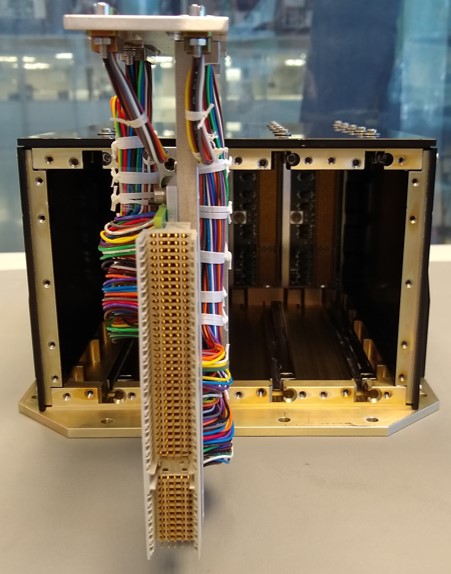

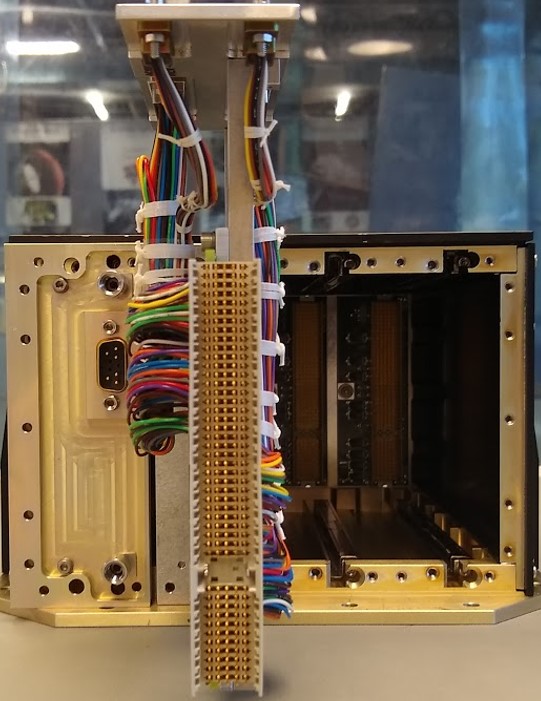

Genesis was a player on Hubble Servicing Missions 1, 2, 3A and 3B. We primarily created protected enclosures to transport new components and retrieve old components back down. Over the course of 4 missions, we transported over 130 flight components to the Hubble Telescope.

Servicing Mission 1

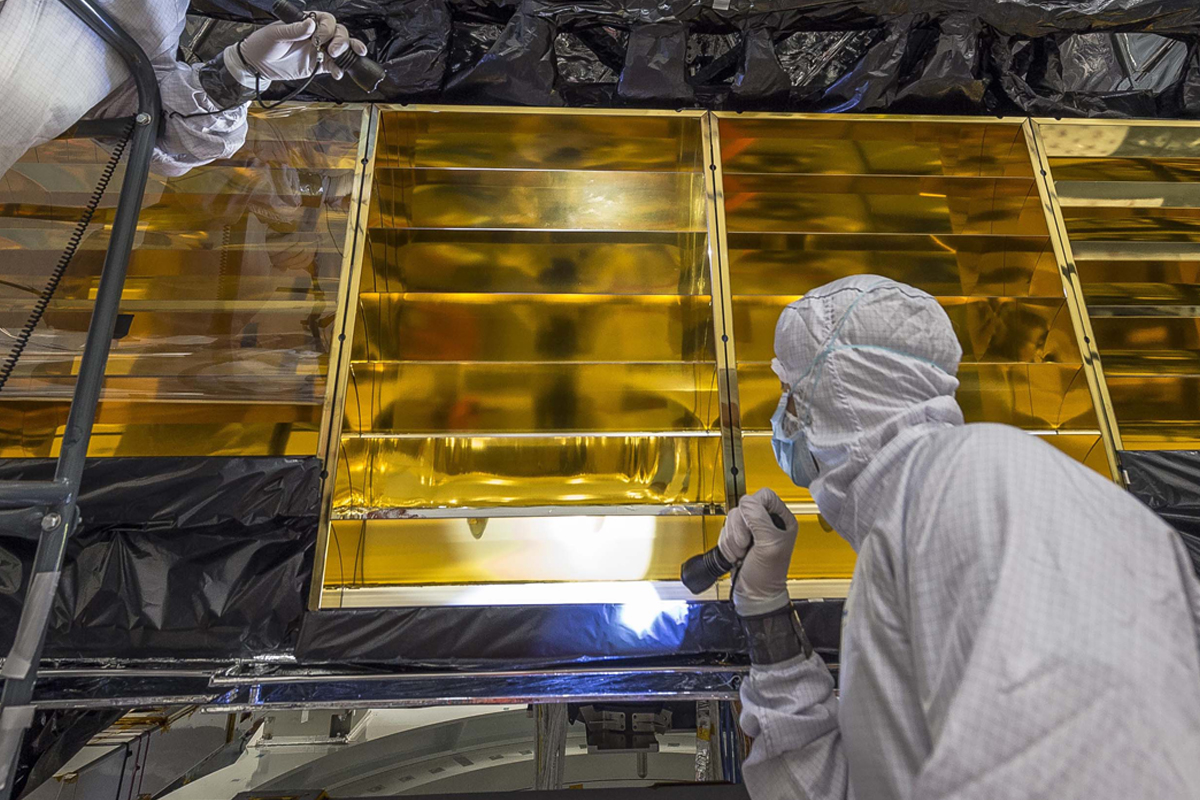

Servicing Mission 1, launch December 1993, was the first opportunity to conduct planned maintenance on the telescope. New instruments were installed and the optical flaw is Hubble’s primary mirror was corrected.

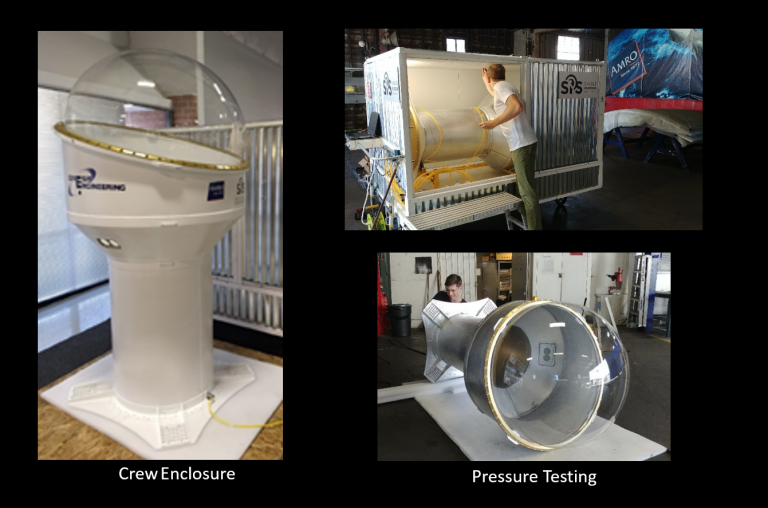

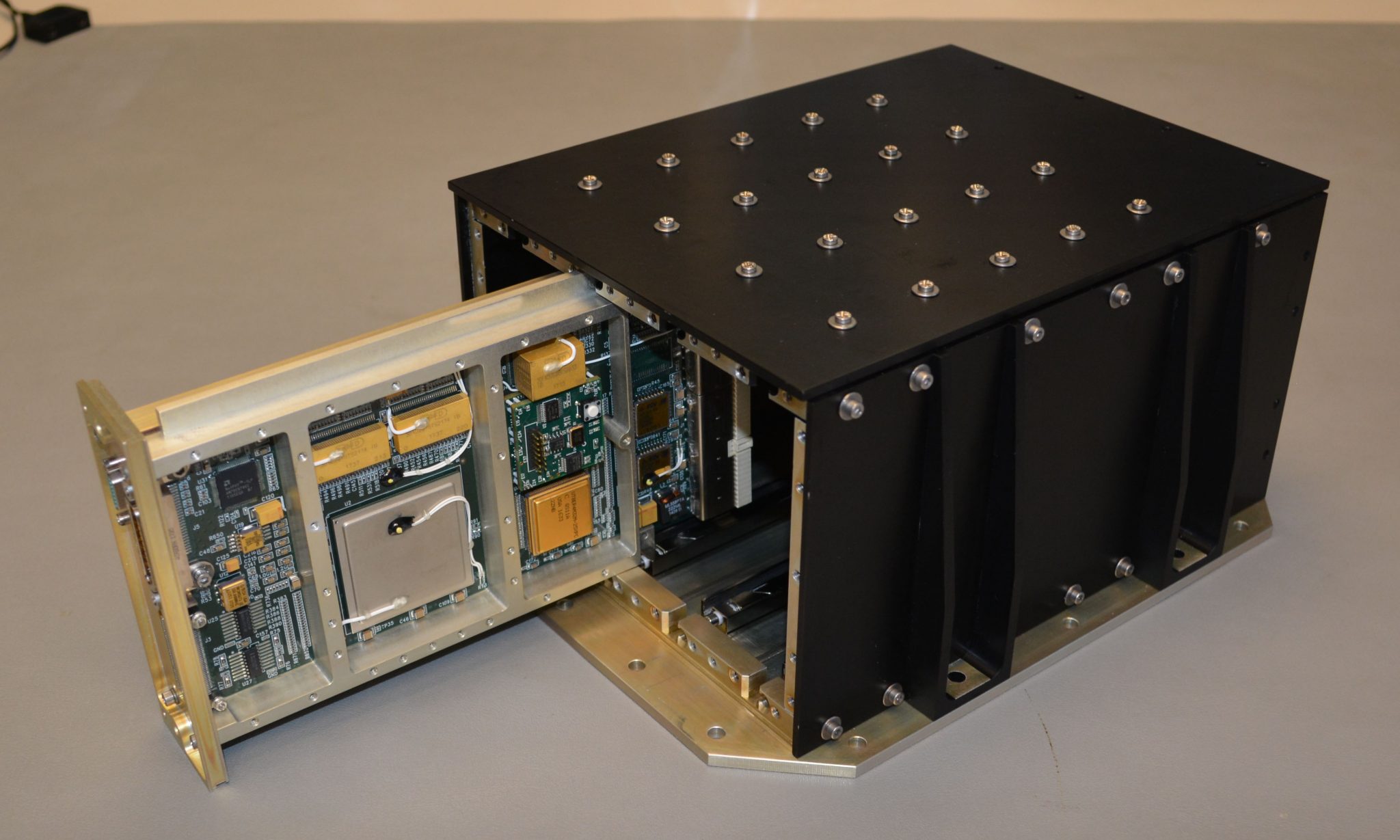

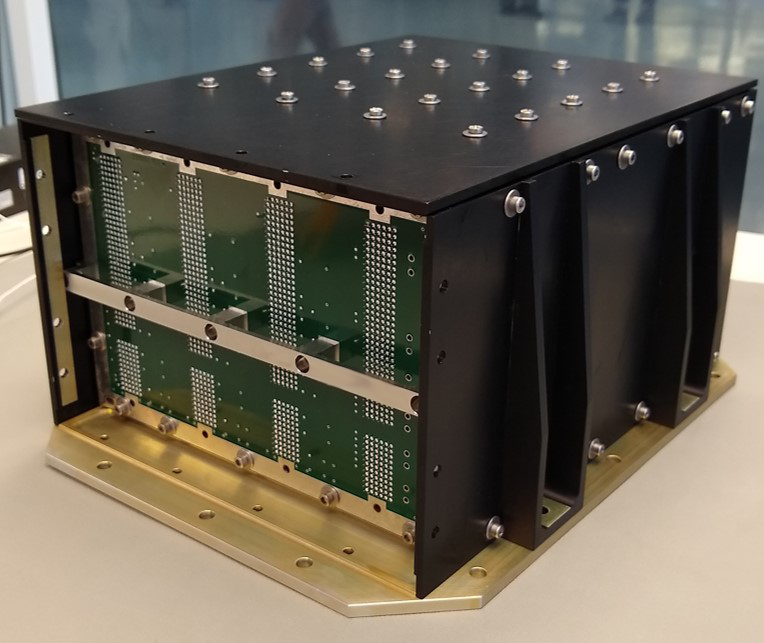

Genesis designed protective enclosures for ORUs (Orbital Replacement Units)

Servicing Mission 2

The Second Servicing Mission, launched February 11, 1997, greatly improved Hubble’s productivity. The installation of new instruments extended Hubble’s wavelength range into the near infrared for imaging and spectroscopy, allowing us to probe the most distant reaches of the universe. The replacement of failed or degraded spacecraft components increased efficiency and performance.

SM 2 Tasks

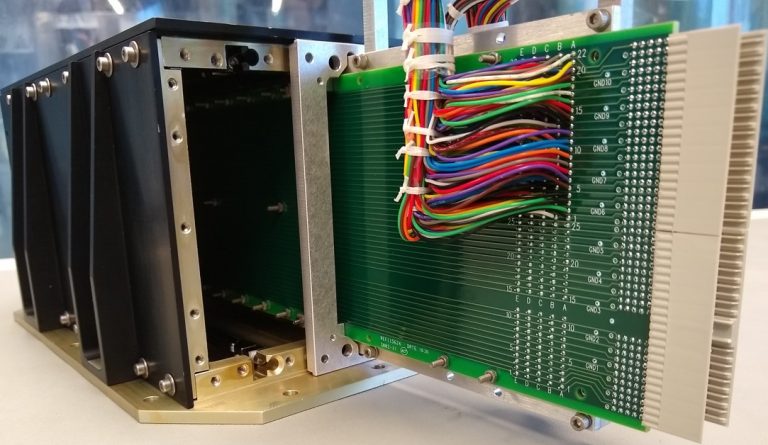

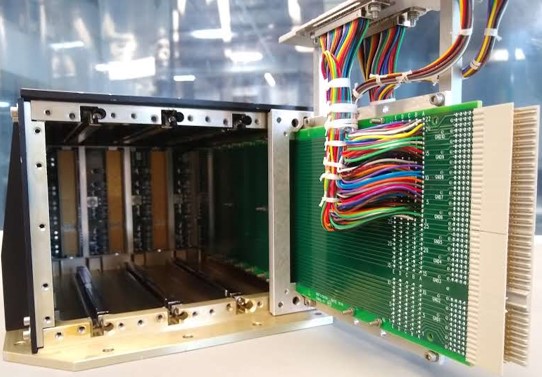

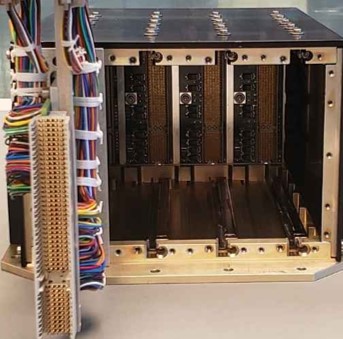

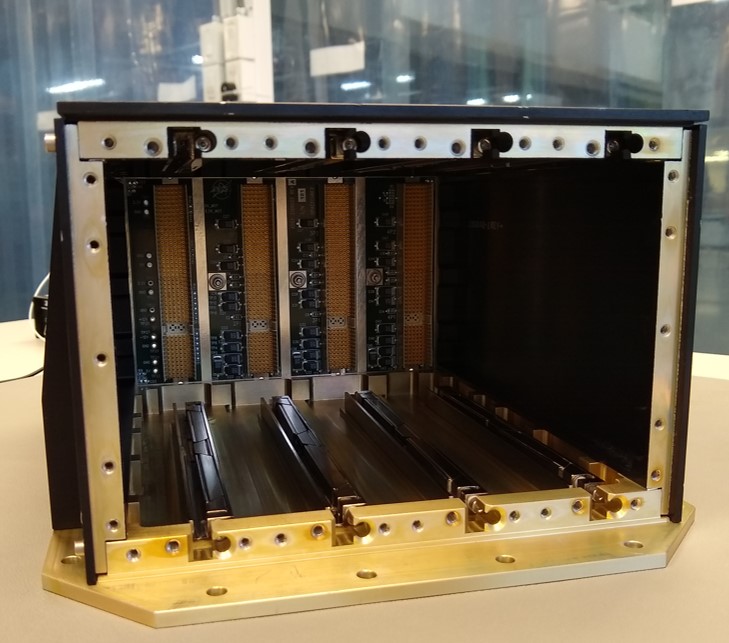

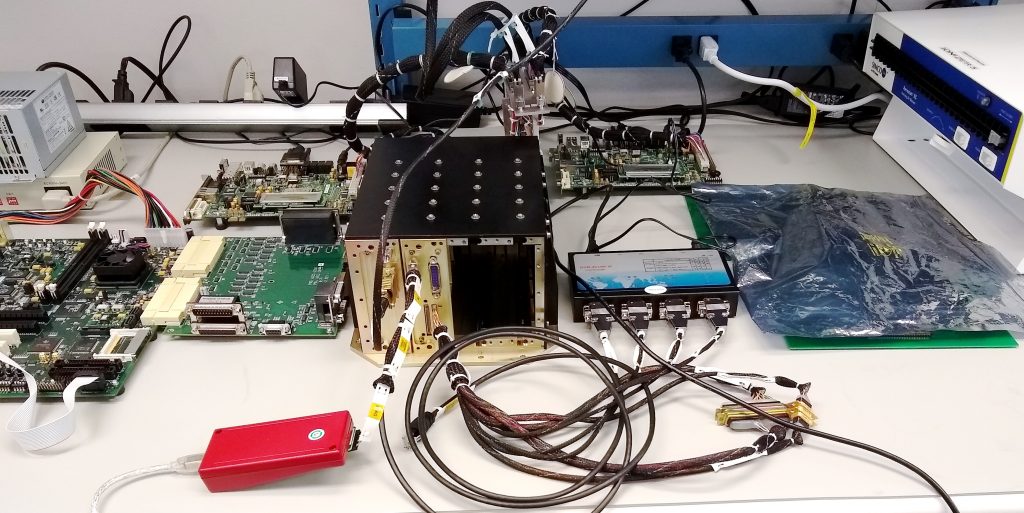

- Designed, built and tested four protective enclosures to support cargo delivery

- Design incorporated innovative “tool-less” EVA interface, heaters and data interfaces

- Performed crew training, built crew training aides and provided crew familiarization support

Servicing Mission 3A

Servicing Mission 3A successfully replaced equipment and performed maintenance upgrades to the Hubble Space Telescope. Although no new scientific instruments were installed, many activities took place over 3 EVA days. The originally planned 4 days of EVA were changed to 3 days because of the weather-delayed launch. The deorbit time was fixed for this mission in order to avoid any possible Y2K problems.

SM 3A Tasks

- Emergency repair mission (4th of 6 gyros failed – 3 required for ops)

- Design and fabrication of protective enclosure vibration isolation systems

- Design and modification of protective enclosures

- Supported training of mission critical personnel and crew

Servicing Mission 3B

During SM3B a new science instrument was installed: the Advanced Camera for Surveys (ACS). Several other activities were accomplished as well over a 12-day mission with 5 spacewalks.

SM 3B Tasks

- Designed, fabricated and built four protective enclosures to support delivery of critical mission hardware

- Supporting neutral buoyancy and crew familiarization

- Provided mission support including ORU integration and de-integration